Latin America. The impact is reflected in the fact that insurers take longer to execute their processes.

The end of isolation measures due to the pandemic, and a return to mass vehicle mobility, brought with it a notable increase in the demand for spare parts.

However, the rupture in the supply chain has generated a shortage of these materials, apart from the difficulty of transporting them. This was stated by the research director of the Center for Experimentation and Road Safety of Colombia (Cesvi), Juan Carlos Ovalle.

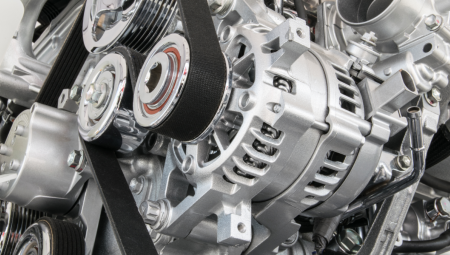

"From the world of collision, there is difficulty in getting auto parts with electrical components such as calculator units, radios, street lamps and among other electronic devices. There is also a lack of structural and removable parts of the body (hood, mudguards, side frames, doors), plastic parts such as bumpers and interior trim parts, in addition the difficulty of finding parts of the suspension cannot be ignored, "said Ovalle.

Cesvi's most recent study on this phenomenon focuses on the impact on insurers, in particular on the response of their services.

According to Cesvi, the processes of compensation of cars are impacted in the maintenance of average costs, dwell times and the increase in applications. Thus, the crisis of spare parts availability has hampered logistics and supply.

A few weeks ago, the same entity had reported that some of the importers of spare parts such as Mazda, Sofasa and Toyota in the country presented decreases in their inventories of spare parts, which ranged between 15% and 35%. Those with the greatest shortage were those most sued for damages caused in cases of collisions.

On the other hand, investment in repair training and the establishment of new parameters in the procedures for obtaining economic agreements with direct arrangements are also taken into account. This is reflected in longer waiting times and higher prices.

The Cesvi reports that the average costs of acquiring spare parts have presented a commercial variation of up to 25% in the course of this last year and a half, compared to the purchase value of the first quarter of 2021.

However, Cesvi himself indicates that one of the actions carried out to mitigate the problem has been to give way to new suppliers and importers. In this way, the repairability of parts is increased, which also affects other agents that are part of the process.