International. The transition from lead-acid to lithium-ion batteries has been critical to the success of electric vehicles (EVs). However, tomorrow demands lighter, more energy-dense and sustainable batteries for the mass electrification of industry.

In the United States, demand for vehicle batteries grew by 80% between 2021 and 2022, while in Mexico, sales of EVs and hybrids grew by 44% in 2023, with EVs expected to account for 50% of sales by 2030, according to Electro Movilidad.

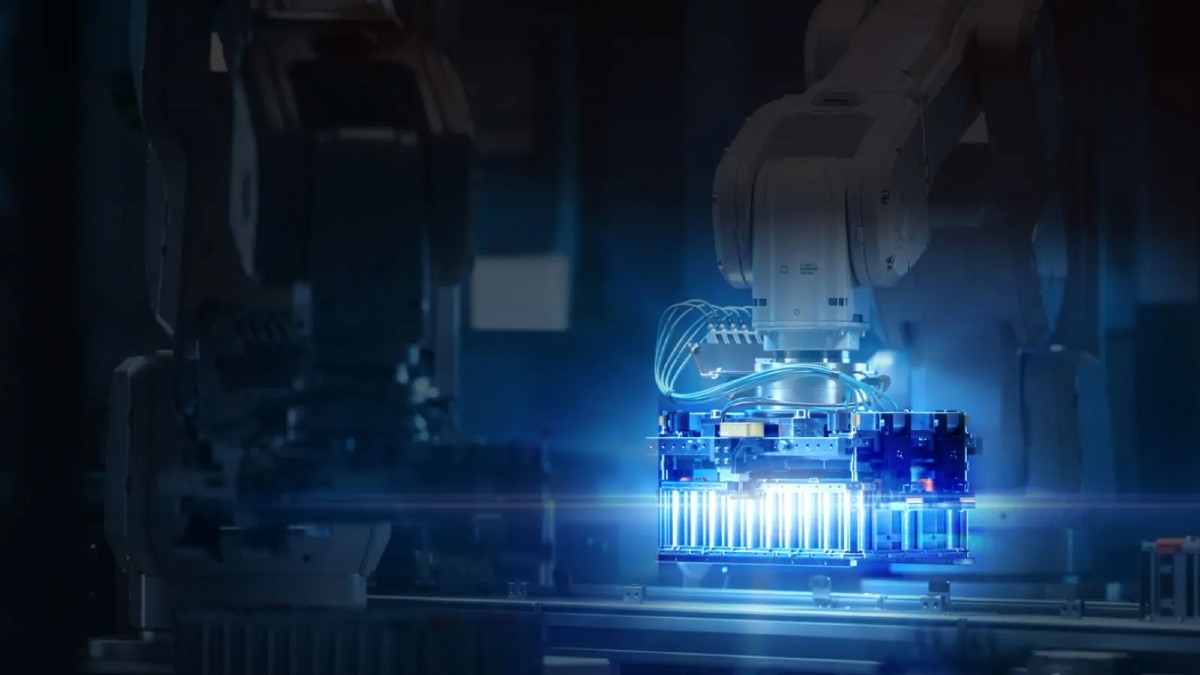

To respond to this explosive growth, battery manufacturing must evolve radically. Dassault Systèmes is spearheading this transformation with cutting-edge simulation technologies covering everything from materials development to large-scale manufacturing. These solutions enable battery manufacturers to innovate effectively in a dynamic and competitive market.

Simulation is crucial to designing safer and more efficient batteries. "The simulation's ability to model complex behaviors from the atomic scale is incredible to help design safer, higher-performing batteries," said Rudy Pastuzak, Director of Battery Industry Solutions Experience, ENOVIA.

System-level simulations model entire battery packs, from the interactions between individual cells and battery management systems (BMS) or degradation mechanisms. And, by reducing prototypes and improving accuracy from the first try, it also means they can deliver next-generation batteries while reducing costs and time-to-market.